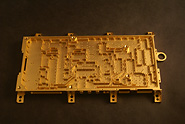

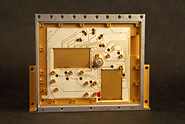

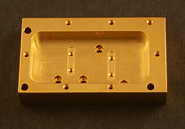

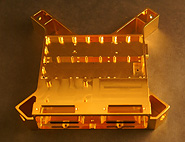

Cunningham Machine was established in 1967 and has been manufacturing precision components for both defense and commercial industries ever since. We are a precision machining facility committed to providing our customers with the utmost in quality and dependability.

We pride ourselves in having a highly skilled work force, combined with state of the art technologies in machine tools, inspection equipment and process sytems. Focused on building long-term relationships, Cunningham Machine is the source

for customers who search for a partner built on lean principles and the delivery of continuous value improvement. We are a Lean Six Sigma Trained facility.

We pride ourselves in having a highly skilled work force, combined with state of the art technologies in machine tools, inspection equipment and process sytems. Focused on building long-term relationships, Cunningham Machine is the source

for customers who search for a partner built on lean principles and the delivery of continuous value improvement. We are a Lean Six Sigma Trained facility.

Cunningham Machine is ITAR registered.

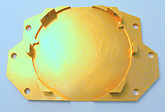

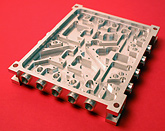

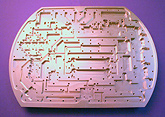

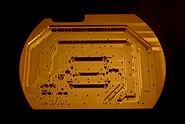

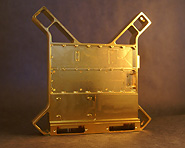

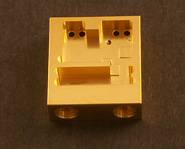

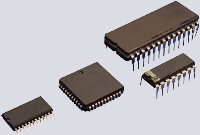

MATERIALS: Much of our expertise is working with materials such as Aluminum, Kovar, Titanium, Magnesium,Steel, Stainless Steel, Copper, Brass, and all types of Plastics.

INSPECTION: Cunningham Machine is ISO 9001:2015 certified. We have a thorough inspection process which yields the highest quality workmanship to our customers. (view our certificate)

PROGRAMMING: Our programming department utilizes only the latest CAD/CAM software from Cam Works, Master Cam and Teksoft. This allows us to meet and exceed our customers requirements.

Cunningham Machine is a veteran owned and operated company

Copyright © 2023 Cunningham Machine Company, Inc.

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

Milling Centers: (1) Matsuura RA-IIF (pallet) (1) Matsuura RA-IF (pallet) (2) Matsuura MC-510VG (2) Matsuura MC-510VF (2) Fanuc Robodrill ALPHA-T21iEL (pallet) (1) Fanuc Robodrill Alpha-D21LiA5 (pallet) (2) Fanuc Robodrill Alpha-D21LiB5 (pallet) (1) Fanuc Robodrill Alpha-D21LiB5 ADV Plus

Turning Centers: (1) Nakamura-Tome AS-200MY, 4500 RPM

Inspection Equipment: (1) Hexagon Global S Coordinate Measuring Machine (1) Brown & Sharpe Microxcel 4.5 4pfx Coordinate Measuring Machine (2) Tesa-Hite 400 Micro Height (2) Tesa-Hite 600 Micro Height (1) Fowler Trimos 300+ Micro Height (3) Nikon SMZ645 Microscope (2) Crystal Pink 2'x3' Surface Plate (2) Crystal Pink 11/2'x2' Surface Plate (1) Grade B 2'x3' Surface Plate (1) Starrett AVR 300 |

Miscellaneous Equipment: (1) Haas Automatic Digital Indexing Head (1) Hardinge 4th axis Trunion (2) Bridgeport Vertical Millers w/digital readout (1) Clausing Colchester Lathe (1) Roper Whitney Pexto Power Shear (1) Wells Metal Cutting Band Saw (1) Dayton Bead Blast Machine (2) Bench Grinders (1) Rockwell Drill Press (1) Sweco Vibro-Energy Tumbler

All other necessary inspection instruments |

|

||||

|

||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

Cunningham Machine Company, Inc.35 Hunt Road Chelmsford, MA 01824 Phone: (978) 256-7541 FAX: (978) 250-9942 If you prefer, us and tell us something about your requirement. |

Cunningham Machine is ISO 9001:2015 Certified and a veteran owned and operated company. |